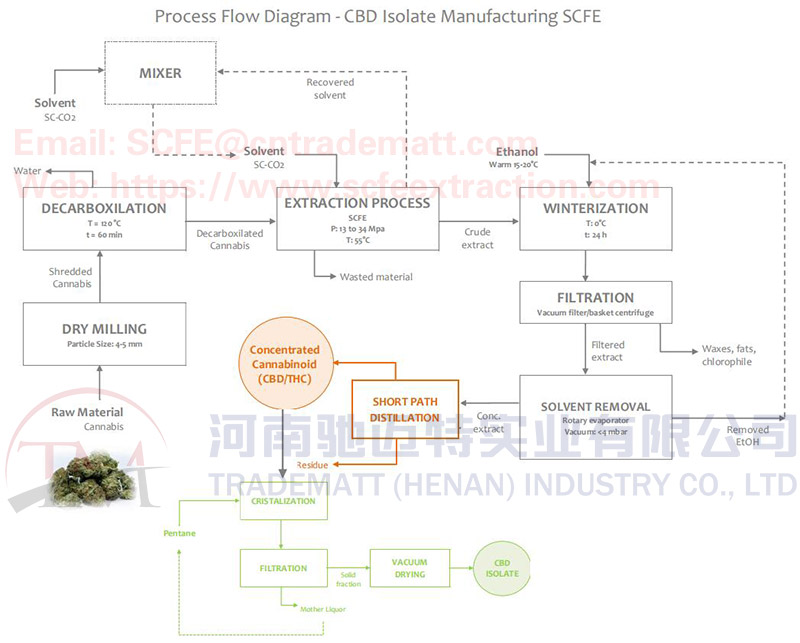

The process starts using Cannabis fresh plant material with a moisture content of 7 – 10% as raw material.

Using a pin milling equipment, cannabis size is reduced to about 3 – 5 mm increasing extraction surface area and therefore cannabinoids recovery efficiency.

Cannabis decarboxylation (transforming acid cannabinoids into their neutral forms with higher activity) is achieved by a heating process under specific time and temperature conditions using a forced ventilation oven. Besides decarboxylation, drying process also reduces initial moisture content of the plant.

The process continues using SC-CO2 as solvent for the extraction. Temperature and contact time conditions between the solvent CO2 and the plant ensure the greatest amount of extractable material with the highest concentration of active compounds. After extraction is completed, wasted material is stored and disposed according to waste management plan and crude extract is winterized and using ethanol and filtered with activated carbon, removing waxes and lipids in the filter cake.

Finally, the filtered extract is fed into a rotary evaporator equipment in order to remove the solvent and concentrate either cannabin oids in the extract. Recovered solvent is reused within the process achieving a reduction in operating costs, while concentrated extract passes through a short-pass evaporator thiat, using molecular distillation, increases the concentration of the cannabin oid of interest(CBD or THC).

After extraction, solvent recovery and SPD steps, concentrated CBD extract is dissolved in pentane at mild temperature and slowly cooled and stored for crystal formation.

Thereafter, crystals are separated from the mother liquor (re-used into the process to save pentane) by filtration and dry under vacuum to reduce heat damage of valuable compounds.

Tags: CBD Isolate Extraction Process, extraction by supercritical fluids, supercritical co2 extraction equipment price